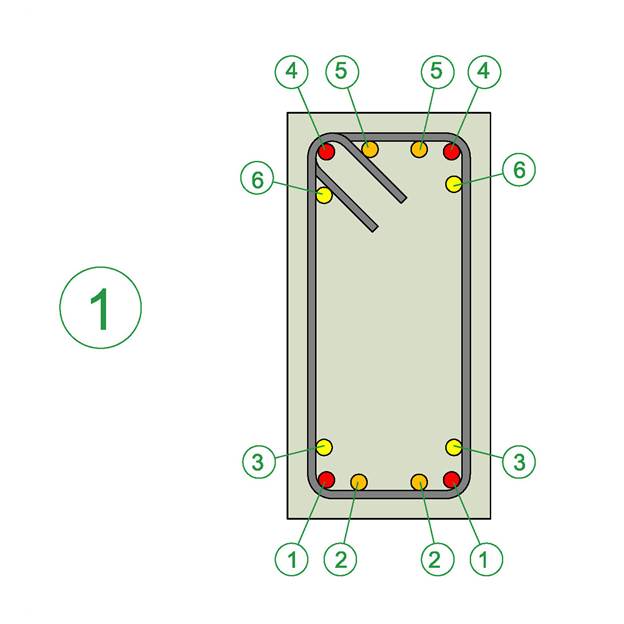

Case (1) shows, in priority order, the possible rebar positions in a rectangular 250/500 beam (with no slab on top).

At the lower part of the beam, the first rebars to place are the corner bars 1, then the internal bars 2 followed by one bar 3 or if it is necessary by a second bar 3.

At the upper part of the beam the same logic apply as well.