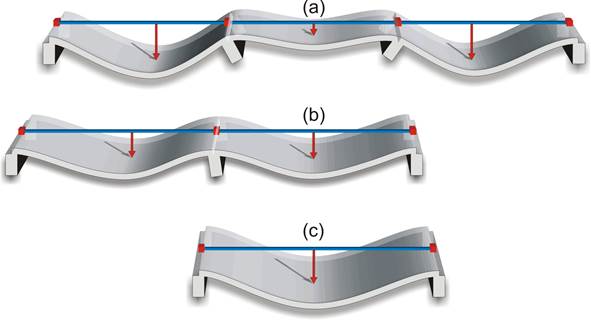

The slab with the bilateral continuity (a) behaves in the best way. Next comes the slab with the unilateral continuity (b) while last comes the slab with no continuity (c)

As regards to support, the safest slab is the two-way slab and the most vulnerable one is the cantilever slab. This happens because in a two-way slab, potential loss of one support results in a two-way three support slab, while in the case of a cantilever slab potential support loss results in collapse.