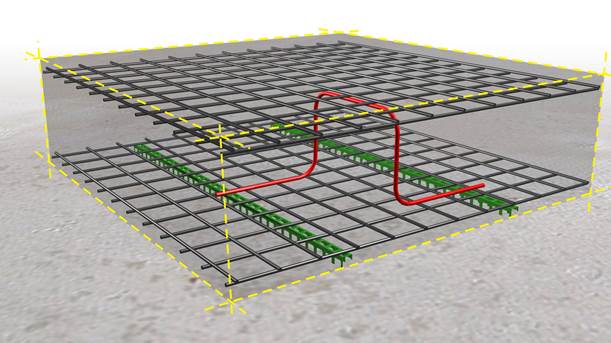

In cases of general or partial raft foundations or when constructing the bottom slab of a pool, the use of rebar mesh as upper reinforcement is necessary.

Just like in superstructure slabs, in the areas around the slab edges, “J-pin” rebars may be combined with open or closed reinforcement mesh.

In the central area, the required cover thickness can be created with the use of special steel rebar chairs placed on top of the lower reinforcement grate.