<project: bkΙnsulationGR>

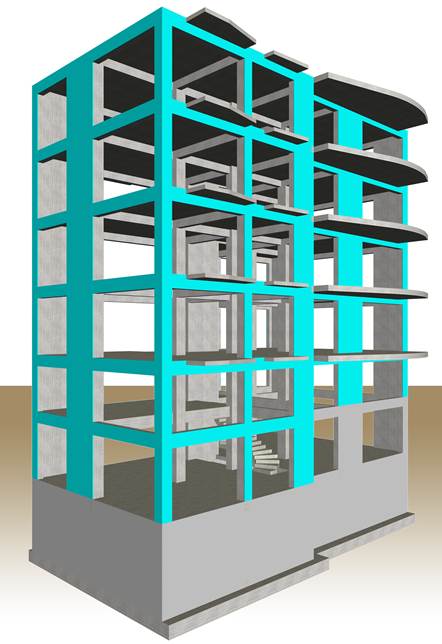

When the thermal insulation is embedded in the exterior or the interior shell of the building and it is independent of the structural frame’s construction, the solution is clear and most of all effective. However, when the thermal insulation is placed on the exterior or the interior surface of the structural frame as part of the total thermal insulation as, for example, in buildings with masonry walls, various issues arise. These include thermal bridges but also constructional matters regarding earthquake resistant behavior.