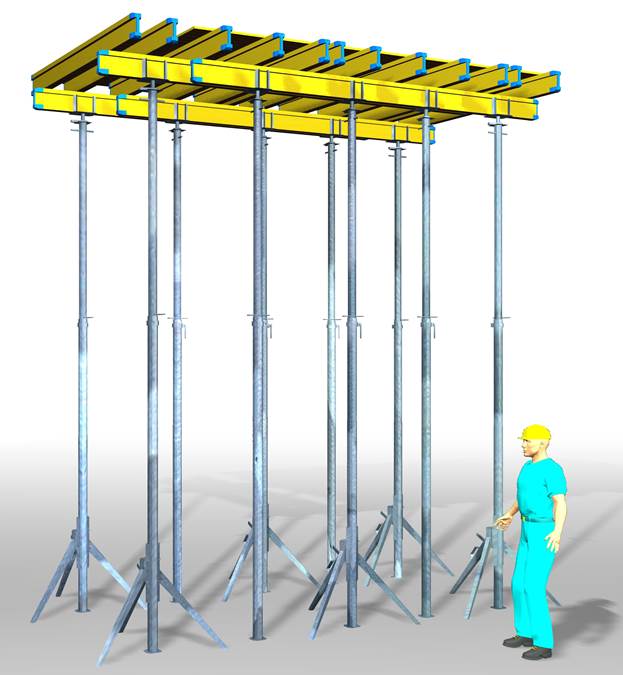

The construction of the beams and slabs formwork is performed with the use of composite, timber I-section beams and shuttering plywood without nailing. Scaffolds are made out of aluminium. Striking (removal) of formwork is performed by releasing the special pins at the top of the scaffold allowing it to controllably recede around 50 mm without damages and without danger of accident.